Enhancing Automotive DC Motor Safety with Fuzetec PPTC Resettable Fuses

Introduction

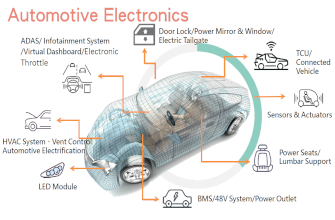

Automotive applications heavily rely on DC motors for numerous functions such as window lifts, seat adjustments, door locks, and windshield wipers. These motors are selected due to their cost-effectiveness, simplicity in control electronics, and reliability in providing the required mechanical movement. However, automotive motors are subject to challenges such as rotor lock, overload conditions, stall current, and overheating, which can cause system failure or even safety hazards. Incorporating protection solutions is essential to enhance the longevity and reliability of these motors.

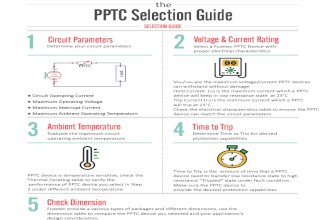

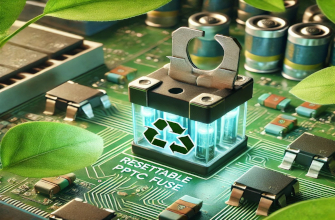

Fuzetec PPTC (Polymeric Positive Temperature Coefficient) resettable fuses offer an effective and reliable solution to protect automotive DC motors from overheating, stall current issues, and electrical stress. In this article, we will explore how Fuzetec PPTC resettable fuses improve the safety of automotive DC motors by providing overcurrent and thermal protection. Additionally, Fuzetec’s AEC-Q200 compliant PPTC products ensure that their performance meets the rigorous standards required for automotive applications.

The Role of DC Motors in Automotive Applications

DC motors are integral components of various automotive applications. They are commonly used in:

Electric windows

Windshield wipers

Seat adjustment systems

Sunroofs

Door locks

The primary function of these motors is to convert electrical energy into mechanical movement through a rotor and stator mechanism. While these motors are widely used due to their advantages, they are susceptible to issues such as:

Rotor Lock: This occurs when the rotor is mechanically blocked, leading to excessive current flowing through the motor's windings.

Overload Conditions: Heavy loads or prolonged use under stressful conditions can lead to overheating and burnout of the motor windings.

Stall Current: A high stall current flows when the motor is powered but prevented from rotating, either due to mechanical resistance or a blockage. Stall current can be several times higher than normal operating current, leading to potential overheating or damage to the motor windings.

Electromagnetic Interference (EMI): The rotational motion of the motor can generate electromagnetic noise, which may degrade the performance of other sensitive automotive electronics.

Addressing these issues requires robust protection components to safeguard the motor and prevent damage. Fuzetec PPTC resettable fuses are a proven solution for providing both overcurrent and thermal protection to automotive motors, ensuring continuous operation without the risk of permanent damage.

Protection Solutions for Automotive DC Motors

When it comes to protecting automotive DC motors, the primary protection strategies focus on preventing overheating, high stall current, and current surges. Two widely used technologies include:

1. Bimetal Protectors

Bimetal protectors rely on a mechanical switch mechanism that disconnects the motor when a thermal overload occurs. While they offer basic protection, bimetal devices present several disadvantages:

They may exhibit contact welding due to constant opening and closing cycles, which reduces their lifespan.

Bimetal protectors allow higher peak temperatures in motor windings, posing a risk of motor failure.

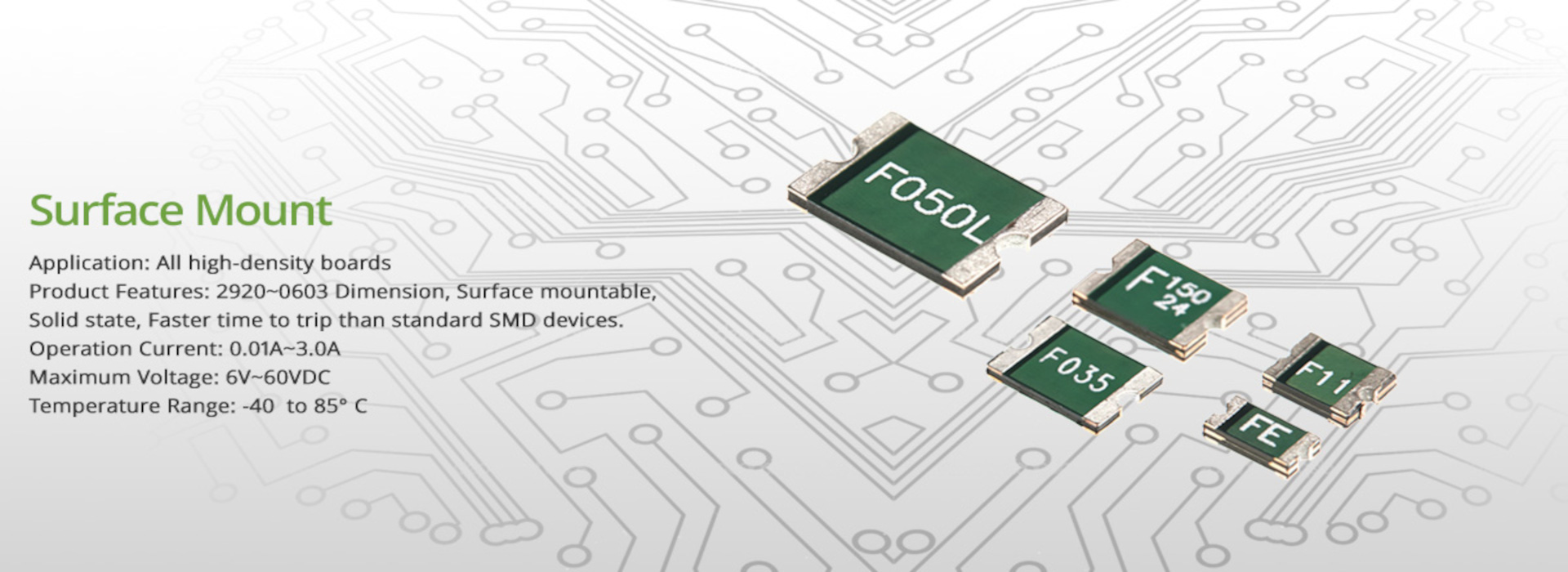

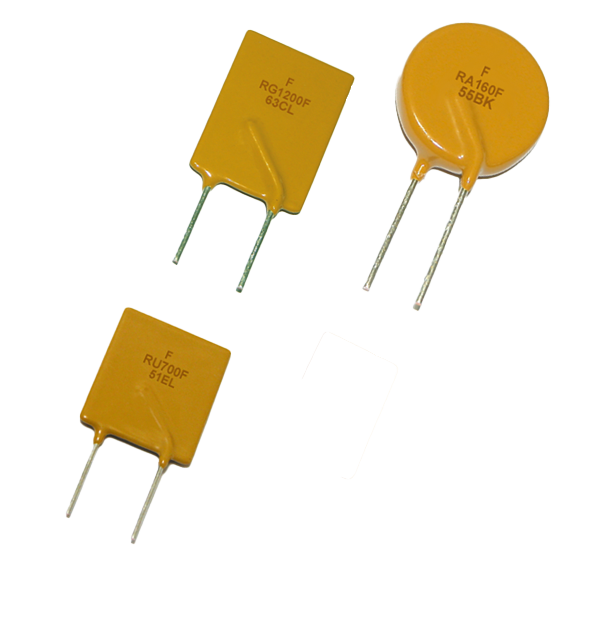

2. Fuzetec PPTC Resettable Fuses

Fuzetec PPTC resettable fuses offer a superior alternative to bimetal protectors by providing faster, more reliable protection with fewer risks of failure. These devices operate based on a thermally sensitive polymer material that increases resistance when an overcurrent, stall current, or thermal condition is detected, effectively limiting the current flow and protecting the motor from damage.

Benefits of Fuzetec PPTC Fuses:

Resettable: After tripping, PPTC devices automatically reset once the fault condition clears, allowing the motor to resume normal operation without requiring a fuse replacement.

No Contact Welding: PPTC fuses eliminate the risk of contact welding and excessive heat buildup, as they have no moving parts.

Compact Design: Fuzetec PPTC devices are designed to fit into tight spaces within motor brush cards, making them ideal for modern, smaller automotive motor designs.

High Temperature Resistance: Fuzetec PPTC fuses can operate at high ambient temperatures, ensuring consistent performance in demanding automotive environments.

AEC-Q200 Compliance: Fuzetec PPTC fuses are compliant with the AEC-Q200 qualification, which is a critical requirement for automotive components. This ensures that the devices can withstand the demanding environmental and electrical conditions found in automotive applications. AEC-Q200 compliance guarantees that Fuzetec PPTC fuses meet high standards for temperature cycling, humidity resistance, vibration, and thermal shock, making them highly reliable in harsh automotive environments.

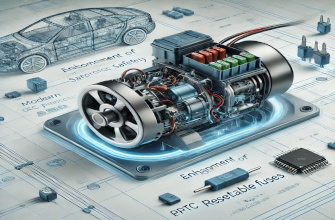

How Fuzetec PPTC Fuses Enhance Automotive Motor Safety

1. Overcurrent Protection

Overcurrent situations can lead to dangerous currents flowing through the motor windings, potentially causing overheating and permanent damage. Fuzetec PPTC resettable fuses respond quickly to excessive current by increasing resistance, limiting the current flow, and preventing damage to the motor.

2. Thermal Protection

Prolonged operation under heavy loads or high ambient temperatures can cause the motor windings to overheat, leading to potential failure. Fuzetec PPTC fuses provide thermal protection by reacting to temperature increases and transitioning to a high-resistance state to reduce current flow and lower the temperature of the motor windings.

3. Stall Current Protection

Stall current is one of the most hazardous conditions for a DC motor, as it can occur when the motor is blocked from rotating. In this scenario, the motor draws significantly higher current than its rated operating current, leading to overheating and potential winding failure. Fuzetec PPTC resettable fuses protect against stall current by rapidly detecting the excessive current and transitioning to a high-resistance state, preventing the motor from overheating and safeguarding the motor windings.

4. Cycle Life and Reliability

Automotive motors, such as those used in power windows or windshield wipers, operate under high cycle conditions, frequently starting and stopping over their operational life. Fuzetec PPTC resettable fuses are designed for high cycle life, ensuring that they do not trip unnecessarily during normal operation but provide reliable protection when needed.

Integration of Fuzetec PPTC Fuses in Automotive Motor Design

Fuzetec PPTC resettable fuses are easily integrated into the brush card assembly of automotive motors. Their low profile and compact size make them an ideal choice for modern motor designs where space is at a premium. Additionally, Fuzetec provides a wide range of PPTC devices tailored to meet the specific protection needs of automotive motors, ensuring compatibility with various motor designs and applications.

By selecting the appropriate Fuzetec PPTC fuse for a given motor, automotive designers can ensure optimal performance and protection without compromising on space or cost. Fuzetec's advanced PPTC technology provides fast response times, stable resistance, and long-term reliability, making them the preferred choice for automotive motor protection. Furthermore, the AEC-Q200 compliance of Fuzetec PPTC fuses guarantees their durability and performance under the harsh conditions of automotive applications, including exposure to extreme temperatures, mechanical stress, and electrical disturbances.

Conclusion

The safety and reliability of automotive DC motors are paramount, given their essential role in various vehicle functions. Fuzetec PPTC resettable fuses offer a comprehensive protection solution by safeguarding motors from overcurrent, stall current, thermal overload, and EMI interference. With their compact design, high reliability, resettable functionality, and AEC-Q200 compliance, Fuzetec PPTC fuses significantly enhance the safety of automotive motors, ensuring long-term operation and reducing the risk of costly repairs or system failures.

For automotive manufacturers looking to improve the safety and efficiency of their motor designs, integrating Fuzetec PPTC resettable fuses is a smart, cost-effective choice. As automotive technologies evolve, Fuzetec continues to develop innovative protection solutions to meet the growing demands of the industry, providing peace of mind for both manufacturers and consumers.

Fuzetec PPTC Resettable Fuse FCTSH48016 for Automotive Power Seat/Lumber support Motor/Solenoid protection.

Details